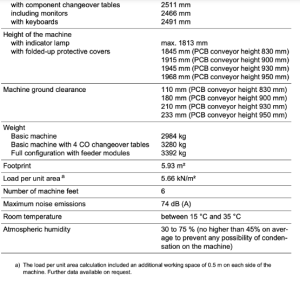

SIPLACE D4i ASM SIPLACE D4I FLEXIBLE SINGLE-GANTRY MACHINES, PICK & PLACE MACHINE, USED SMT MACHINE

ASM HIHG SPEED PLACEMENT MACHINE used SIPLACE D4i for sale, excellent condition, less working hours, optional configuration 81,500 CPH

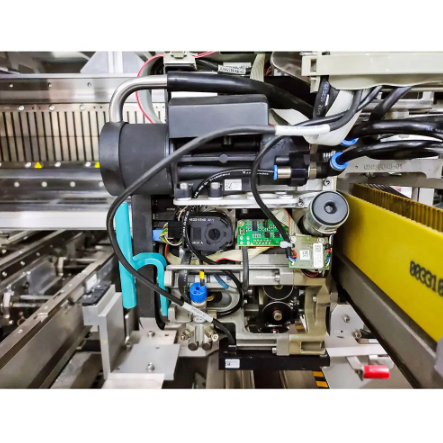

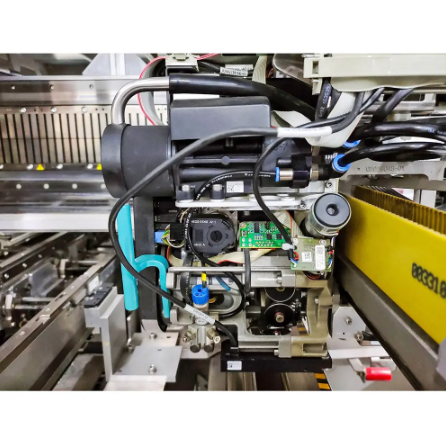

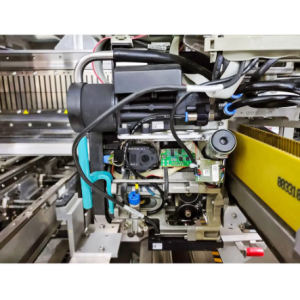

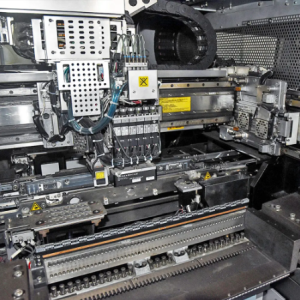

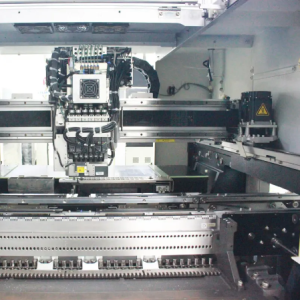

Placement Head With the SIPL ACE D4i, we can provide a potent placement machine with four gantries and four 12-nozzle Collect & Place heads. It is thus a high-speed placement machine that combines a high placement rate with placement accuracy and flexibility. Collect& Place principle The SIPLACE 12-nozzle Collect & Place head works on the Collect & Place principle. This means that, within each cycle, 12 components are picked up and “collected” by the placement head, are optically centered on the way to the board, and are rotated into the required placement angle. They are then placed gently and accurately on the PCB. This principle is particularly suitable for the high-speed placement of standard components.

Checking and self-learning functions The SIPLACE placement heads’ reliability can be further increased with various checking and self-learning functions. • Component sensor It checks for the presence of a component at the nozzle before and after the nozzle before and after pick-up and placement process It • Digital camera on the placement head Checks the position of each component at the nozzle. Any deviations from the required pick-up position are corrected before placement takes place. ks on within •Force sensor Monitors the specified component set-down forces. With the sensor stop method, differences in height during pick-up and any unevenness of the PCB surface are compensated during placement. y ed en • Vacuum sensor peed Checks whether the component was picked up or set down correctly.

Digital Vision System The digital SIPLACE vision system automatically saves the last 500 images of components that were identified as “bad”. SIPLACE users can then easily demonstrate poor component quality. The benefits at a glance: • Maximum placement quality • High first pass yield • Reduced operating costs

Đánh giá

Chưa có đánh giá nào.