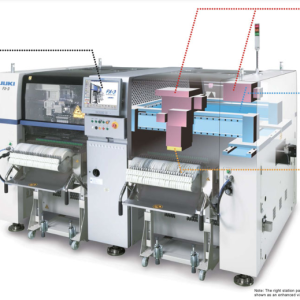

JUKI KE-2060M SMT PLACEMENT, CHIP MOUNTER, PICK AND PLACE MACHINE, USED SMT EQUIPMENT

High-speed flexible mounter All-round surface mounter with Yamaha’s 1- head solution delivers superior productivity and versatility! 12,500 0603(0201) CPH to 74mm

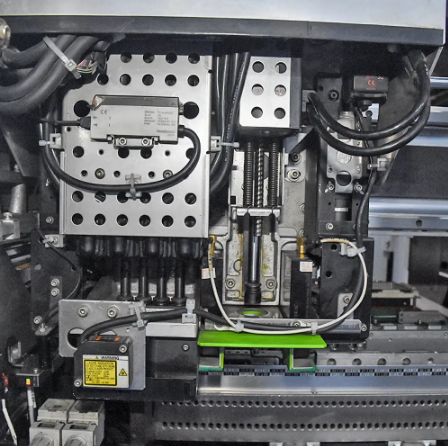

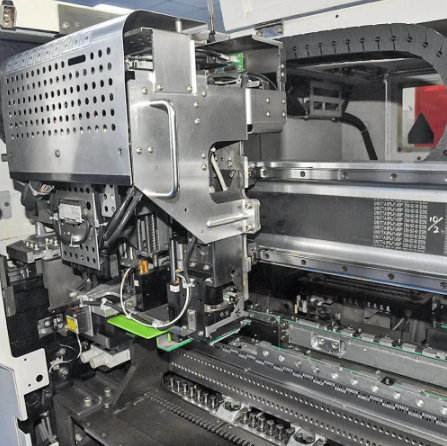

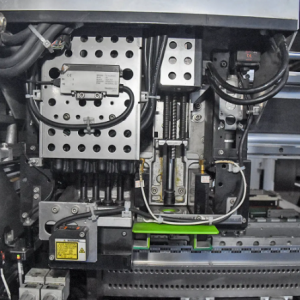

JUKI’s unique component recognition system Dual use of laser and vision (featuring bottom, side, and back lighting) recognition systems.

Recognition method can be chosen for chip placement, based on the shape, size and material of components. Laser for high-speed placement and vision for flexible placement. With the combination of nozzles designed for odd-shaped components and the vision recognition system, the KE-2060s component placement capability is unsurpassed.

General Vision function is used to support a wide variety of today’s unique and vision-centered components. While programming, the data input can be verified for completion on the preview monitor. Additionally, component outer recognition, selection of lines or corners of components can be viewed on the monitor, providing further ease of

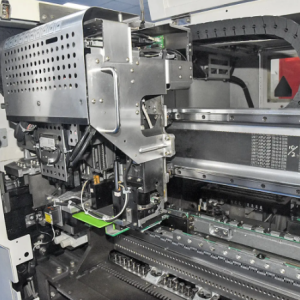

Cluster Optimization A “Cluster” is a group of feeders that can be used for more than one production file. The feeders required for several different production files are grouped into a single feeder configuration, or cluster, thus eliminating the need for changeover between different boards. The clustered feeders, which are used on more than one production file are assigned first, then other feeders, which are used on a single program are set assigned.

Auto Production Download The production data is automatically uploaded into HLC from the machine when placement is completed, and HLC software automatically downloads the next production program into the machine. Once change over is completed, the machine starts placing the next program

Đánh giá

Chưa có đánh giá nào.